Established in 1982, Certified Metal Finishing (CMF) has earned its reputation as a leading provider of aluminum anodizing and metal finishing services. Our team is known for delivering high-quality, and on-time service for mission-critical industries–including MRO, defense, aerospace, marine, medical, automotive, and electronics. With a range of in-house processes and deep expertise in complex specifications, we prioritize precision, quality, and customer satisfaction–because you and your industry demand nothing less.

Strategically located between West Palm Beach and Miami, FL, USA

Serviced to the Highest Standard

We are compliant to thousands of SPMs and CMMs, and we comply to a drug-free workplace.

Services & Specs

Chromic Anodize, also known as Type I Anodize, creates a thin, corrosion-resistant oxide layer on aluminum, ideal for flexible, fatigue-resistant parts like landing gear in aircraft. CMF offers multiple seals (Hot Water, Nickel Acetate, Dichromate, PTFE).

Specifications

- MIL-PRF-8625 Type I & IB Cl 1 & 2

- AMS 2470

- MIL-STD-171

Sulfuric Anodize, or Type II Anodize, forms a thicker oxide layer on aluminum, enhancing corrosion resistance and paint adhesion, commonly used for durable aircraft components. CMF offers colors (black, blue, red, gold, gray) and multiple seals (Hot Water, Nickel Acetate, Dichromate, PTFE).

Specifications

- MIL-PRF-8625 Type II Cl 1 & 2

- AMS 2471

- AMS 2472

- MIL-STD-171

Hardcoat Anodize, also known as Type III Anodize, produces a thick, hard oxide layer on aluminum, improving wear resistance that is essential for high-abrasion areas like engine parts in FAA repairs and engineering development. CMF offers colors and multiple seals (Hot Water, Nickel Acetate, Dichromate, PTFE).

Specifications

- MIL-PRF-8625 TYP III Cl 1 & 2

- MIL-A-8625 TYP III Cl 1 & 2

- AMS 2469

- AMS 2482

- MIL-STD-171

These coatings protect metals like aluminum with a thin, non-buildup layer, using trivalent or hexavalent chromium, meeting FAA corrosion standards.

Specifications

- MIL-DTL-5541 TYPE I&II (All Classes)

- MIL-C-5541

- AMS 2473

- MIL-STD-171

This process applies a protective layer to magnesium, improving corrosion resistance for lightweight aircraft parts, crucial for FAA applications.

Specifications

- AMS-M-3171 TYPE I

Passivation removes free iron from stainless steel, forming a protective oxide layer to prevent rust, vital for FAA component longevity and safety.

Specifications

- QQ-P-35

- AMS-QQ-P-35

- FED-QQ-P-35

- AMS 2700 TY II, VI & VIII

- ASTM 967 NITRIC 1 & 2

- ASTM A380

Humidity Testing assesses how materials perform under high moisture, ensuring FAA components can withstand humid environments without failure.

Specifications

- ASTM D 2247

- ASTM 967 Practice B

Salt Fog Testing exposes materials to salty conditions, evaluating corrosion resistance, essential for FAA parts in marine or coastal operations

Specifications

- ASTM B 117

- ASTM 967 Practice C

The Copper Sulfate Test checks for free iron on stainless steel, verifying passivation effectiveness, a key quality control for FAA safety.

Specifications

- AMS 2700

- MIL-STD-753 Method 102

- ASTM 967 Practice D

Vacuum Impregnation seals porosity in castings, preventing fluid leaks, ensuring integrity of critical FAA components like engine parts.

Specifications

- MIL-STD-276 (Less pressure test)

This process includes the chemical removal of previous coatings in addition to mechanical cleaning of the product in accordance with CMMs or SPMs.

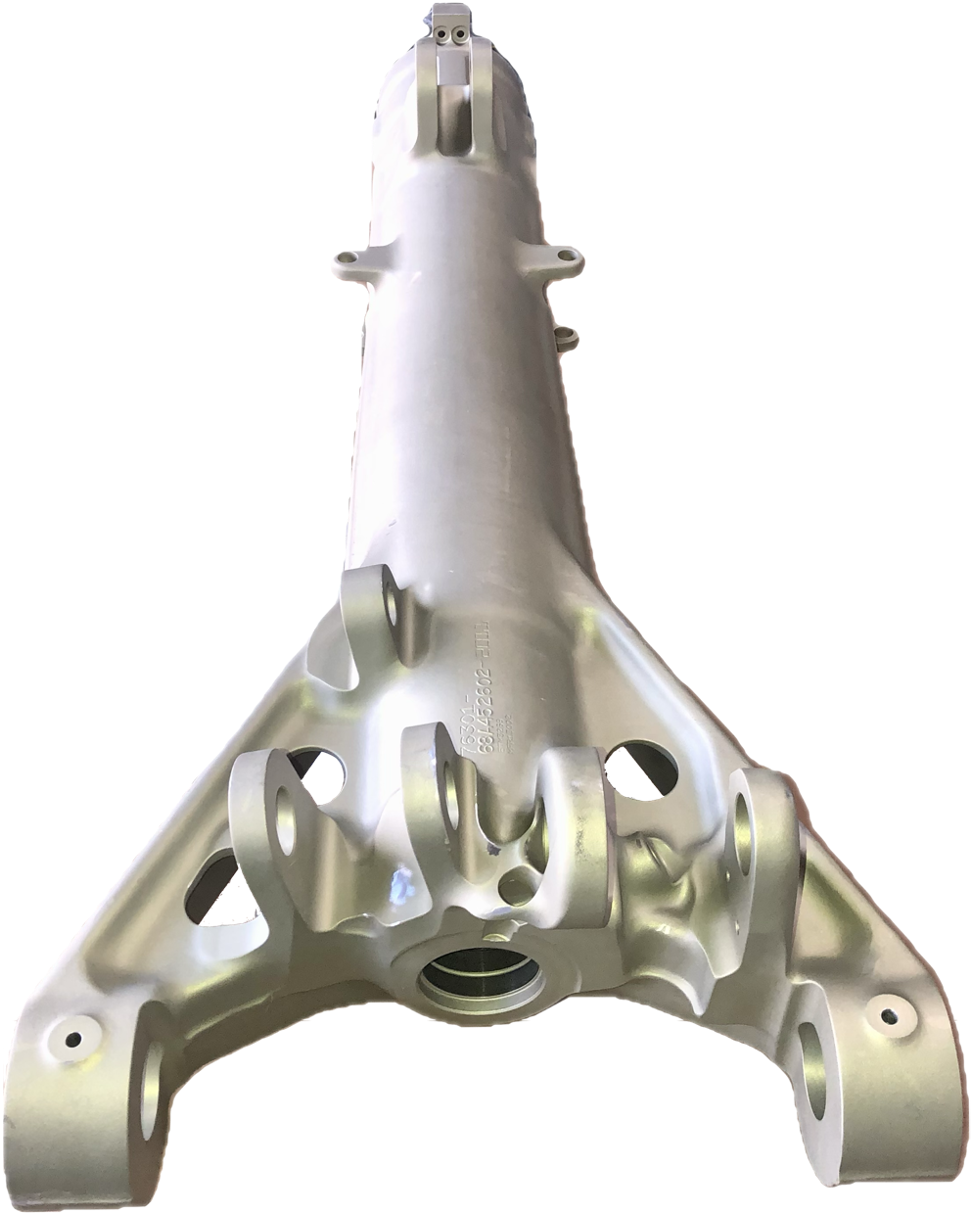

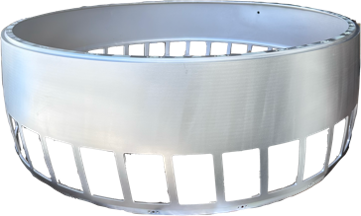

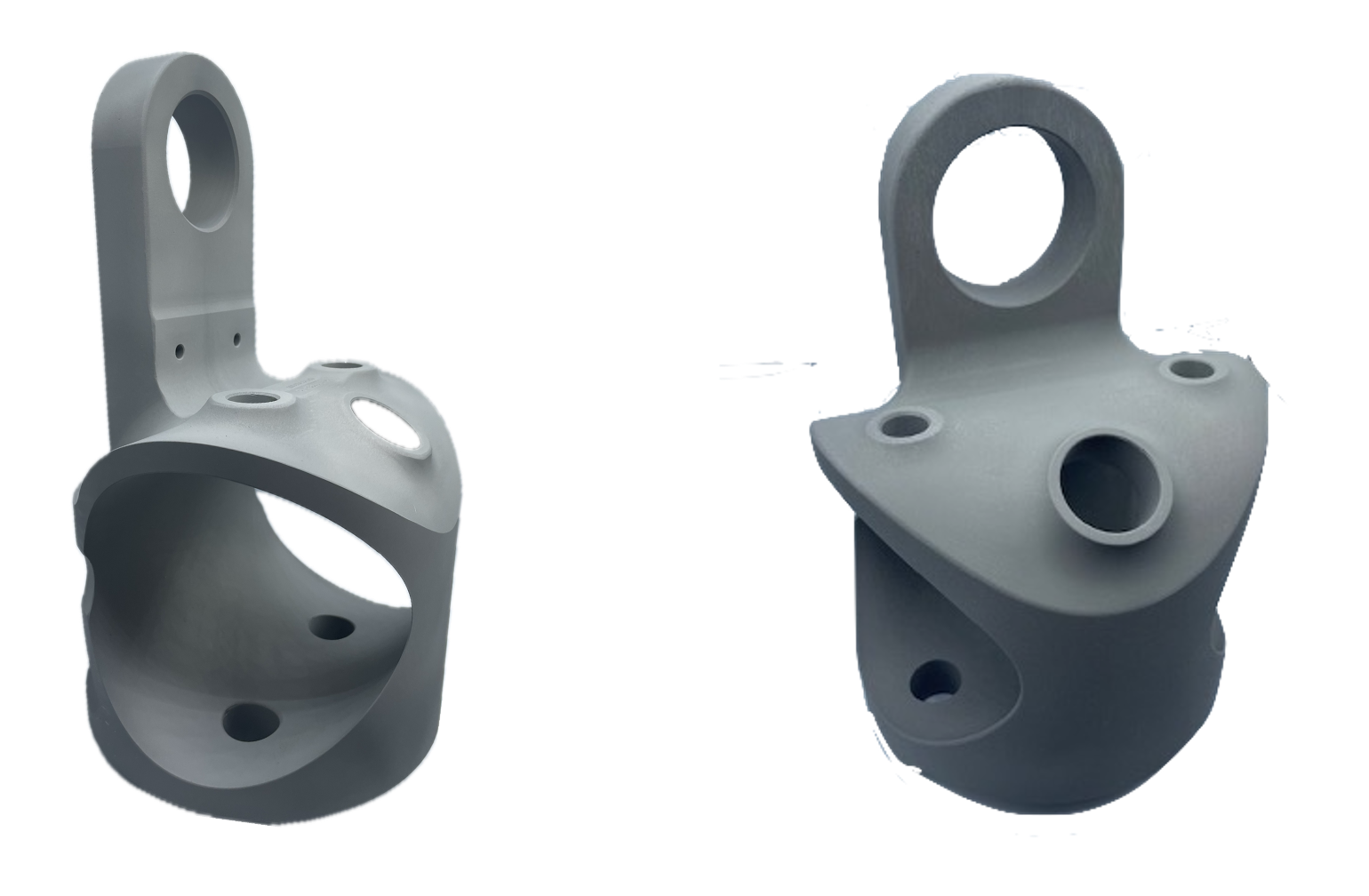

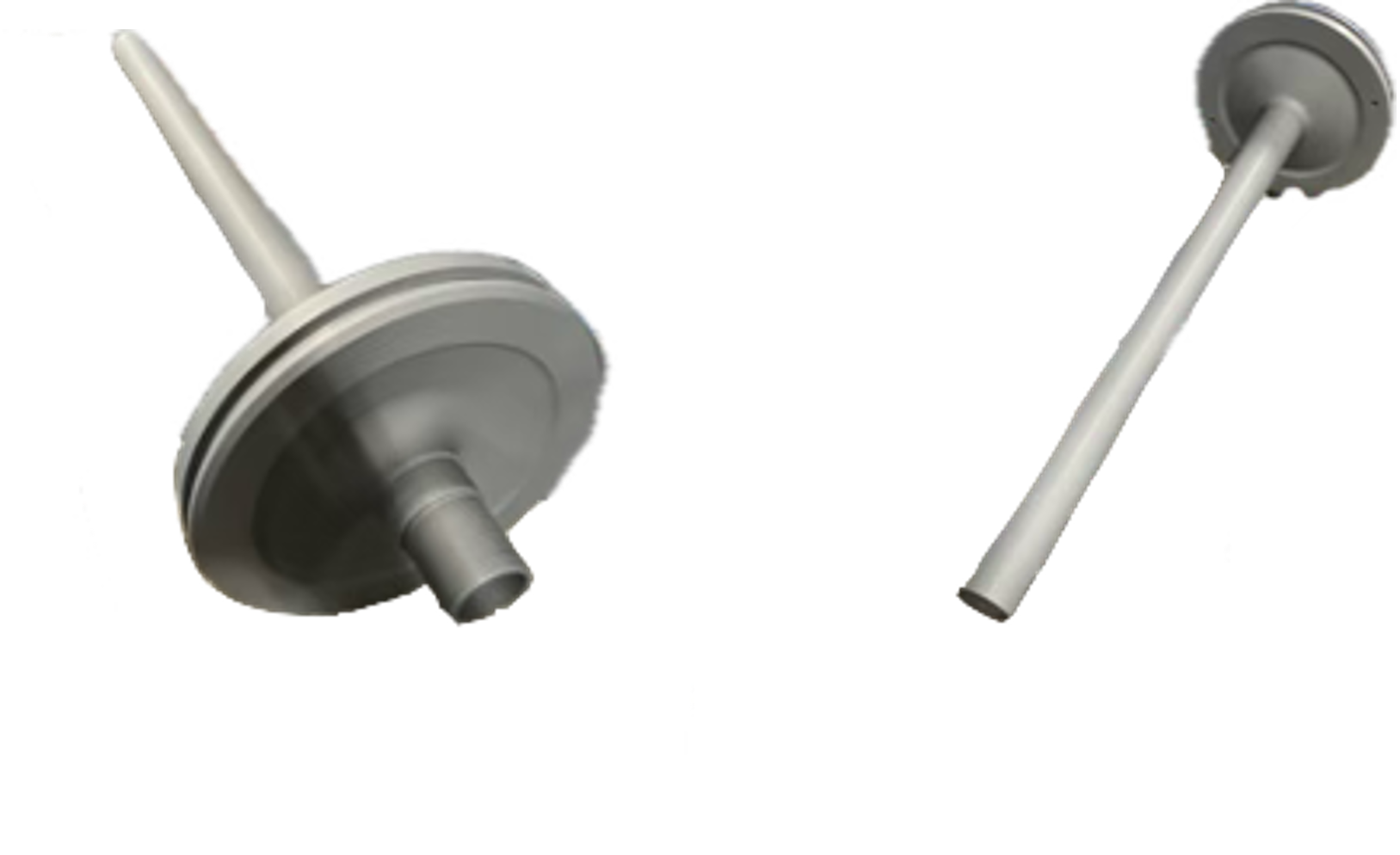

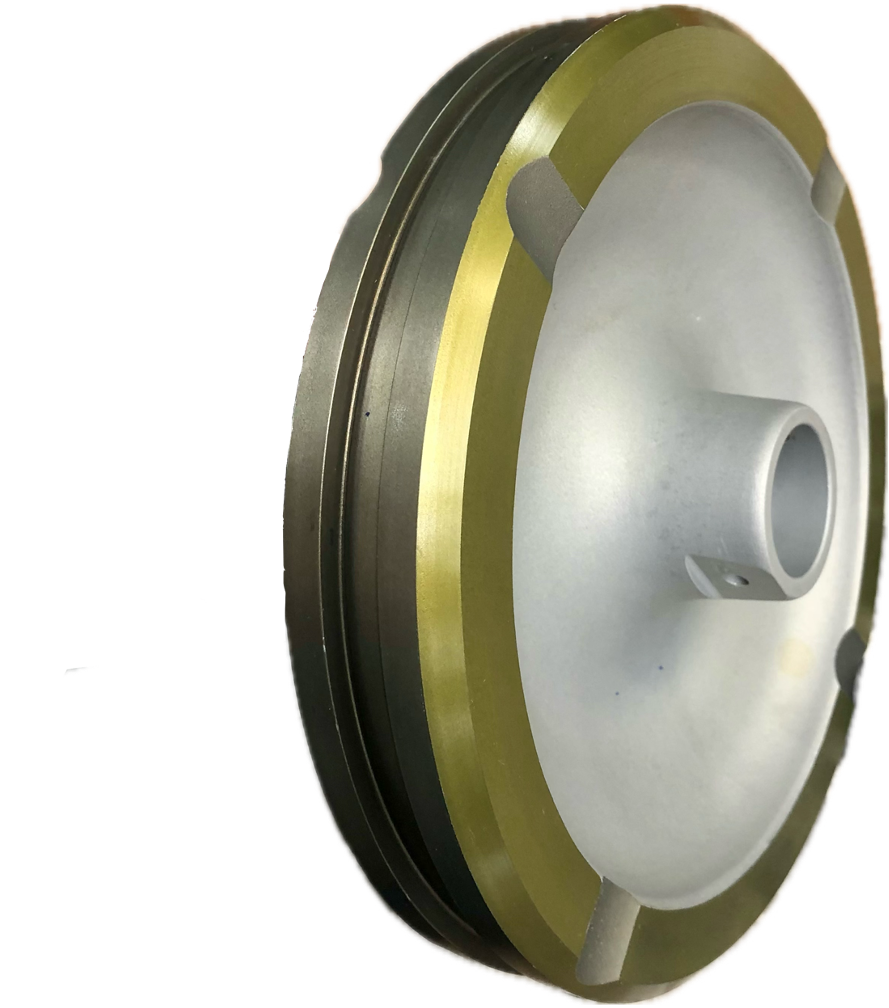

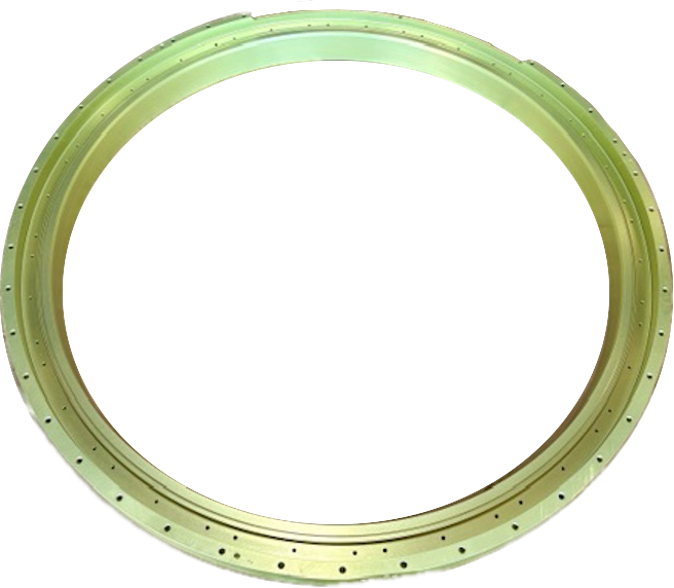

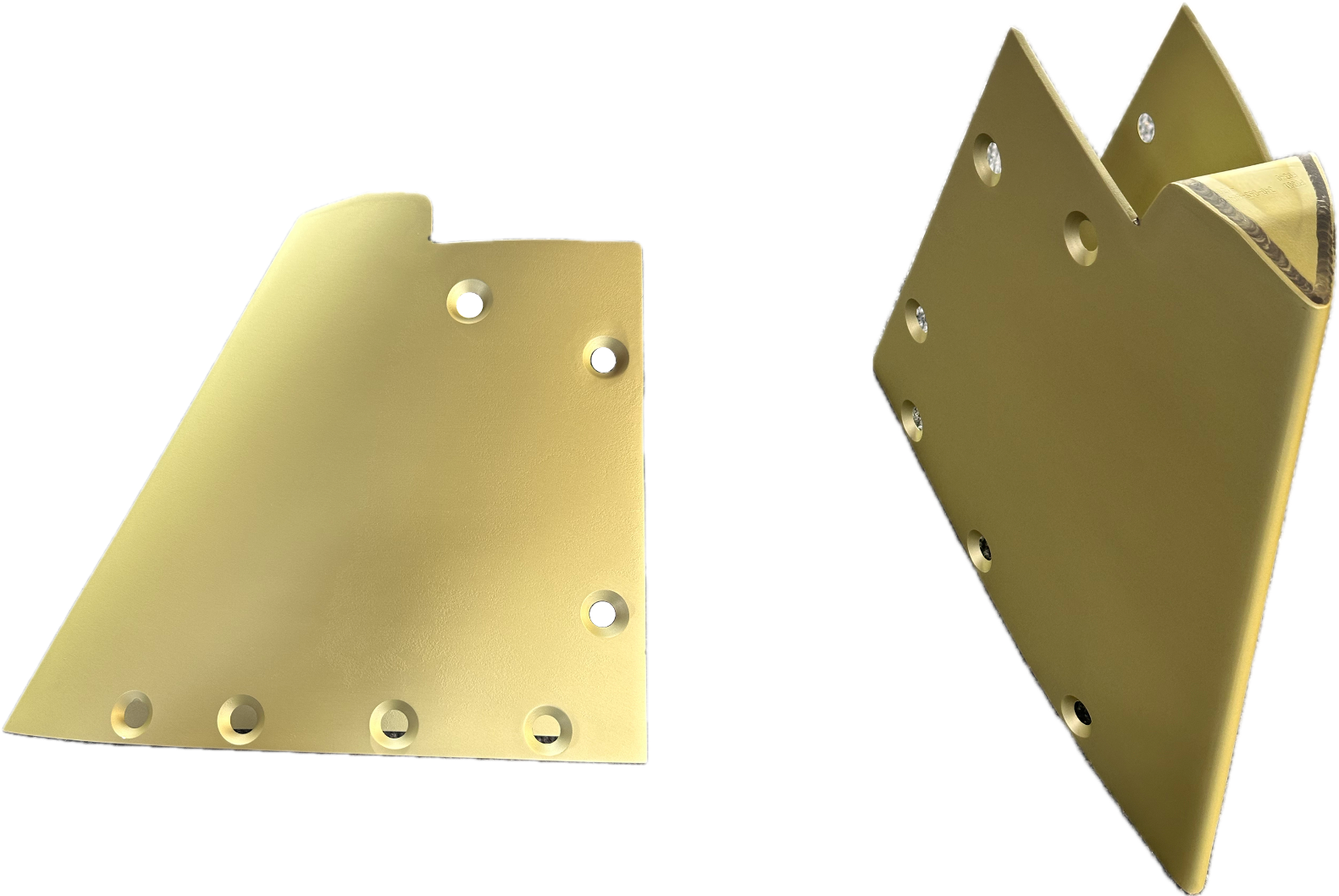

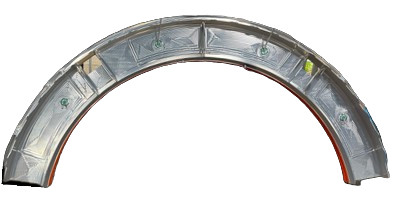

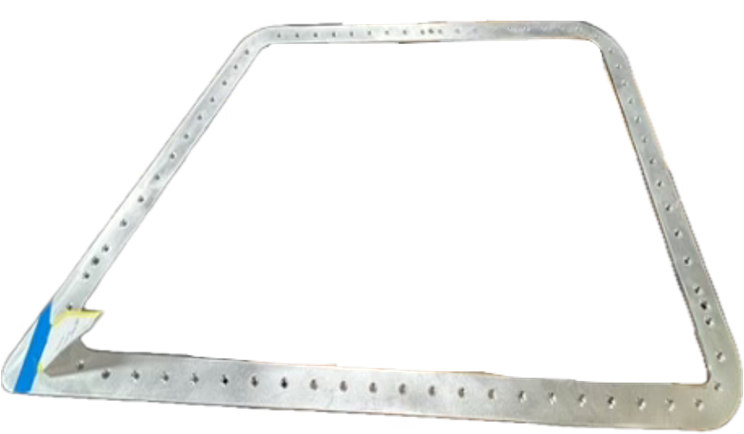

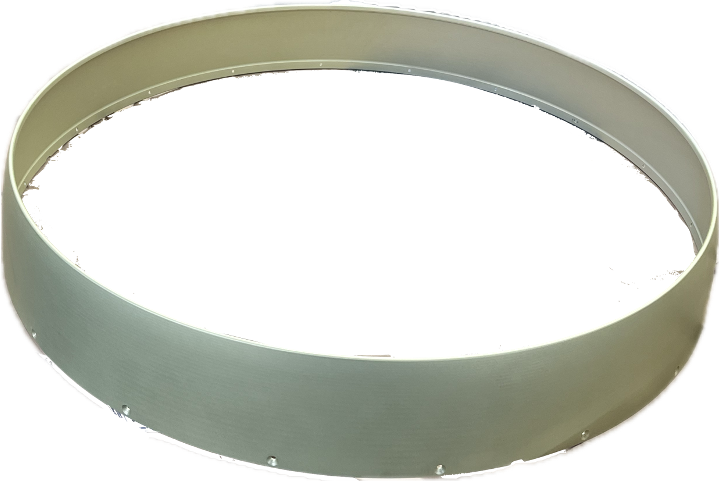

Preview Our Work

Download Our Booklet of PartsNot Finding What You’re Looking For?

Our team is here to guide you with unmatched technical support

Call Us NowApply Now Form

×"*" indicates required fields